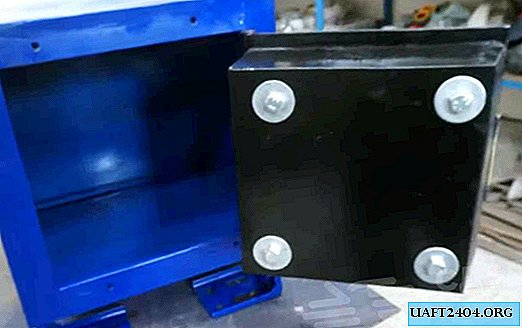

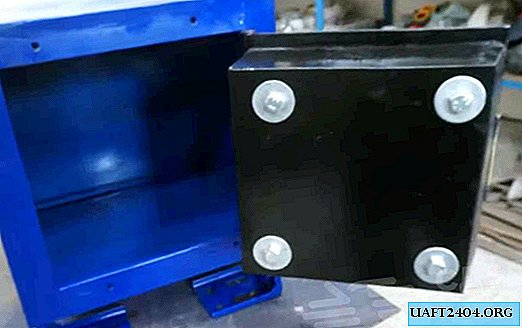

This review shows the process of making a safe with a secret, which is suitable for home use.

For its manufacture, thick sheet metal with a thickness of at least 6-8 mm will be required.

And first of all, we cut out the blanks of the required size from sheet metal. Then we weld a square box from them.

The author cuts out strips from sheet metal and welds them from the inside of the box.

The main stages of work

At the next stage, the master makes the legs that need to be welded to the bottom of the box. Four metal corners are used for this.

Then it will be necessary to cut out the door (it is advisable to use metal thicker for this), and with the help of canopies we attach it to the box - on the side where the strips are welded.

The master attaches a padlock to the inside of the door. To fix the lock, you will need to weld two small plates.

After that, from the pieces of metal, the author welds another square box, which must be welded to the inside of the door.

The secret of this safe is the side wall of the inner box. And it closes with a simple hidden lock.

For details on how to make a compact home safe with your own hands with a secret, see the video.