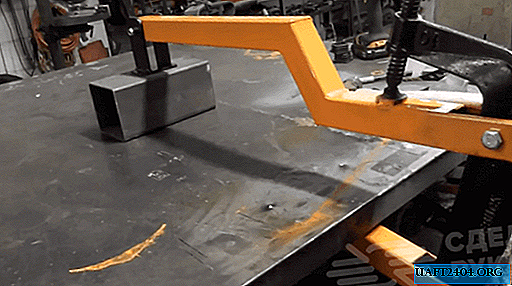

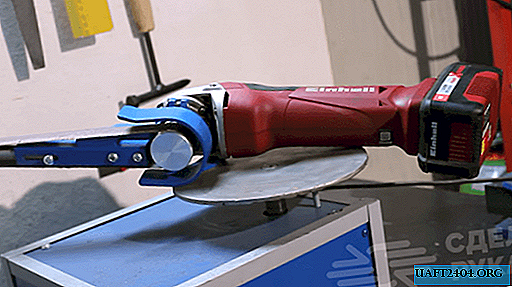

With this home-made rack, you can withstand the horizontal level of pipes, rods, fittings, and other metal workpieces longer than 3-4 meters when cutting them on a miter saw. To make such a useful fixture for the home workshop, the following materials will be required:

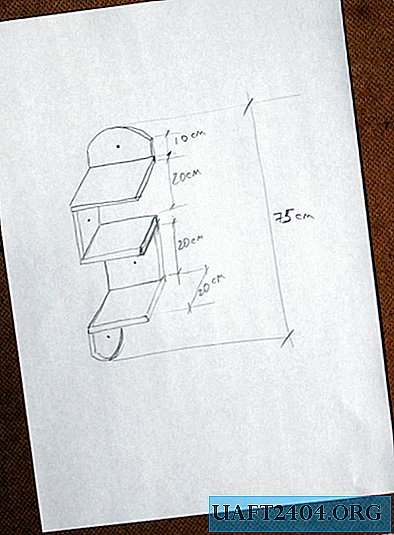

- profile pipes of square section 65 cm and 50 cm long;

- two round water pipes 45 cm long;

- one rectangular profile 41 cm long;

- round pipe with pressed bearings;

- two segments 27 cm long, one of the sides of which is cut at an angle of 45 degrees;

- two pieces of a steel plate 14 cm long with a hole.

The plates need to be welded along the edges of a rectangular profile 41 cm long perpendicular (at right angles). In the center, it is necessary to weld a square profile pipe with a length of 65 cm. To the pipe section of 50 cm on one side, using welding, fix short segments of 27 cm at an angle of 45 degrees.

Homemade Rack Assembly Process

Round pipes are welded perpendicularly to the edges of these segments. Then the two main parts of the structure are “joined” together. To fix the profile pipe with the pieces of plates in a vertical rack, it is necessary to drill a hole for the M12 bolt.

A M12 nut is welded to the pipe, and a piece of steel bar or strip as a handle is attached to the cap of the bolt by welding. A stud is inserted into the pipe with bearings, which must be inserted into the holes in the plates, fixed at the edges with nuts. After that, all structural elements must be cleaned and painted if desired.