A conventional wood sander is cheaper than an oscillating tool. Therefore, if you need a vibrating cutter, then you can make it yourself from an old grinder. In principle, a new one can be used if you buy a budget model.

Universal vibration cutter is an indispensable tool in the country, as well as in the home workshop. Due to the limited rotational moment, the oscillating tool has lower productivity than, for example, a grinder or a manual circular tool.

However, this also has its advantage - the vibrating cutter is more practical and much safer to use. Due to the small amplitude of the oscillations, there is practically no recoil effect. Moreover, the scope of this multitool is wide enough.

Step-by-step homemade manufacturing process

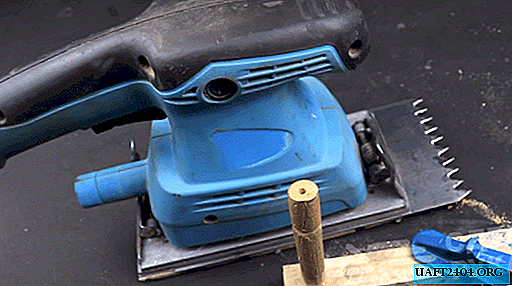

No modifications will be made to the design of the grinder. First you need to make nozzles for work. To do this, cut a piece of sheet metal to the size of the sole of the grinder, and cut out the teeth with a grinder.

We remove the pressure plate from the sole of the grinder and apply it to the nozzle to mark the places for drilling holes for the screws. Then we install the nozzle on the sole of the grinding machine and fix it with the pressure plate.

The oscillating instrument is now ready for use. For example, it can be used to cut various lumber from wood or drywall. The process of manufacturing a homemade vibrating cutter from a simple grinder, see the video on our website.