In the process of manufacturing various products or processing wood blanks, it is necessary to organize a convenient workplace. A loyal assistant in the home workshop for each joiner is a bench vise for working with wood.

Moreover, home-made vices are quite versatile - for example, they can be used to fix small bench vices. In this case, you do not have to drill through holes in the workbench itself.

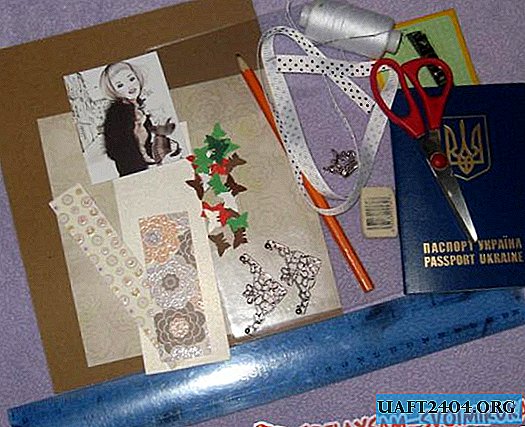

First, cut off the screw of the desired length. He will also need to pick up a nut, which must be screwed onto one end of the screw. Then we put the sanitary tee on the other end - it will be necessary to drill a hole in it.

The main stages of work

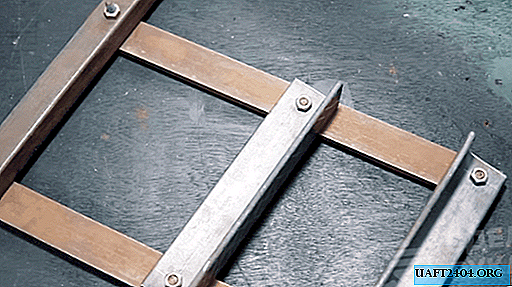

The clamping jaws of a bench vise can be made of plywood. But for this you will need to glue together several pieces so that the thickness of the workpiece is at least 40 mm. We cut the resulting workpiece in half, and then drill holes for the screw and guides.

In the movable hold-down sponge, you will additionally need to make a recess under the nut. Then we install the nut in the seat (if necessary, you can cut it off), screw a screw into it, and put the plumbing tee on the free end, which is fixed with a bolt.

At the last stage of work, we attach a fixed sponge to the workbench, then we install steel guides from a round bar, and we connect all this with a movable clamping sponge. We also make a handle for the winch.

For more information on how to make home-made bench vice with your own hands for processing wood blanks, see the video on the website.