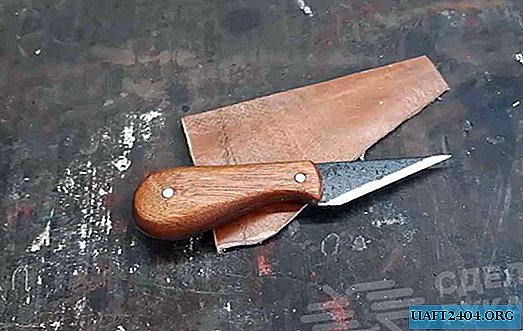

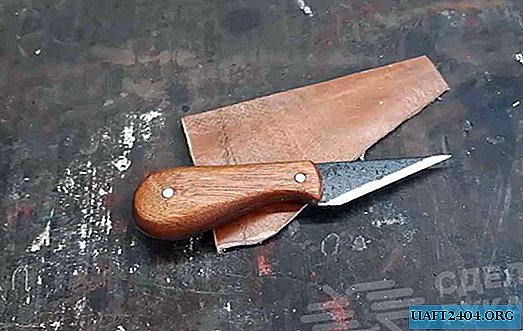

If you work a lot with the skin, then you will need a good and most importantly - a comfortable knife. Buying it is not necessary - you can do it yourself.

You will need a piece of sheet metal (you can use a saw blade) and a wooden block.

First of all, on a piece of paper we draw a sketch of the future knife by hand (or you can find a ready-made sketch on the Internet). Then we cut out the template, apply it to a piece of metal and draw a marker around it.

Next, cut the blank for the knife with a grinder. Edges need to be processed with a file or a petal disk for angle grinders.

The main stages of work

At the next stage, we mark and drill two through holes in the workpiece. This can be done on a drilling machine or with a drill.

After that, you need to sharpen the blade on a grinding or grinding machine.

According to the shape of the tail of the knife, the author cuts wooden blanks (two halves of the handle). Two holes must be drilled into them. Then glue to the knife shank.

Next, we process the handle on the grinding machine and then manually with sandpaper.

At the last stage, the author cuts two pins and inserts them into the drilled holes, having previously spread them with glue. The protruding edges are cut off with a grinder flush with the handle.

Then it remains only to cover the handle with mineral oil, which will extend its service life and visually make it more attractive.

For more information on how to make a convenient knife for working with leather from available materials, see the video below.