Share

Pin

Tweet

Send

Share

Send

To power various electronic devices and do-it-yourself circuits, you need such a power source, the output voltage of which can be regulated over a wide range. With its help, you can observe how the circuit behaves at a particular supply voltage. At the same time, it should be able to produce a large current in order to supply a powerful load, and minimal ripple at the output. A linear voltage regulator is perfectly suitable for the role of such a power source - the LM338 microcircuit, it provides a current of up to 5 A, has protection against overheating and short circuit at the output. The scheme for its inclusion is quite simple, it is presented below.

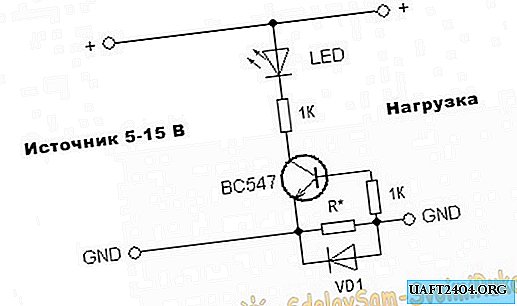

Scheme

The LM338 chip has three outputs - input (in), output (out) and control (adj). We apply a constant voltage of a certain value to the input, and remove the stabilized voltage from the output, the value of which is set by a variable resistor P2. The output voltage is adjustable from 1.25 volts to the input voltage, minus 1.5 volts. Simply put, if the input, for example, is 24 volts, then the output voltage will vary from 1.25 to 22.5 volts. It is not necessary to apply more than 30 volts to the input, the microcircuit may go into protection. The larger the capacitance at the input, the better, because they smooth out the ripple. The capacitance at the output of the microcircuit should be small, otherwise they will retain a charge for a long time and the voltage at the output will be adjusted incorrectly. In addition, each electrolytic capacitor must be shunted with a film or ceramic with a small capacity (in the diagram it is C2 and C4). When using a circuit with high currents, the chip must be installed on the radiator, because it will dissipate the entire voltage drop on itself. If the currents are small - up to 100 mA, a radiator is not required.

moschnyj-linejnyj-stabilizator-naprjazhenija.zip 22.03 Kb (downloads: 403)

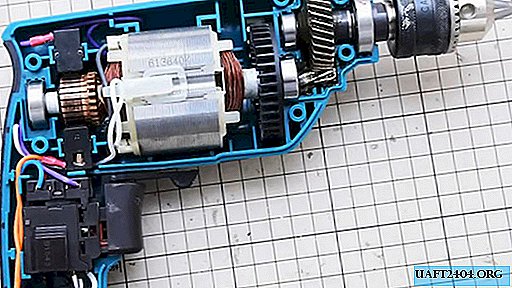

Stabilizer assembly

The whole circuit is assembled on a small printed circuit board measuring 35 x 20 mm, which can be made using the LUT method. The printed circuit board is completely ready for printing, you do not need to mirror it. Below are some photos of the process.

It is desirable to tear the tracks, this will reduce their resistance and protect against oxidation. When the printed circuit board is ready, we begin to solder the parts. The chip is soldered directly to the board, with the back to the side of the edge. This arrangement allows you to fix the entire board with the microcircuit on the radiator. A variable resistor is output from the board on two wires. You can use any variable resistor with a linear characteristic. At the same time, its average output is connected to any of the extreme ones, the two contacts received go to the board, as seen in the photo. To connect the input and output wires, it is most convenient to use a terminal block. After assembly, it is necessary to check the correct installation.

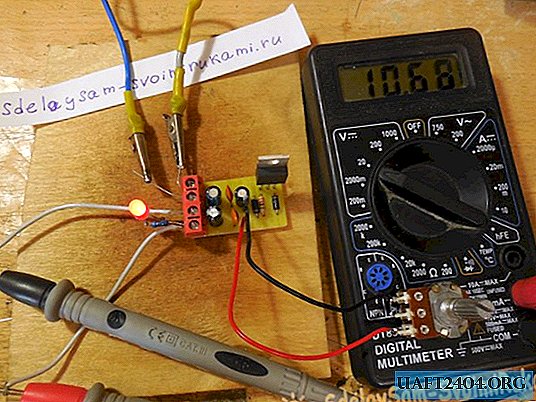

Launch and testing

When the board is assembled, you can proceed to the tests. We connect a low-power load to the output, for example, an LED with a resistor and a voltmeter to control the voltage. We apply voltage to the input and monitor the voltmeter, the voltage should change when the knob rotates from minimum to maximum. The LED will change the brightness. If the voltage is regulated, then the circuit is assembled correctly, you can put the chip on the radiator and test with a more powerful load. Such an adjustable stabilizer is ideal for use as a laboratory power supply. Particular attention should be paid to the choice of microcircuit, because it is very often faked. Fake microchips are cheap, but they easily burn out at a current of 1 - 1.5 Amperes. The original ones are more expensive, but honestly they provide the declared current up to 5 amperes. Successful assembly.

The video clearly shows the operation of the stabilizer. When the variable resistor rotates, the voltage smoothly changes from minimum to maximum and vice versa, while the LED changes brightness.

Share

Pin

Tweet

Send

Share

Send