Share

Pin

Tweet

Send

Share

Send

To make devices for drilling boards, I do not use purchased cartridges and other parts is very simple. I have drilled more than one hundred holes in home-made circuit boards with such a drill from a motor in my time. The time spent on the manufacture of this device will take no more than 10 minutes.

Of course, you can drill not only textolite boards, but also plastic, thin metal such as aluminum, etc.

Prior to that, I used a hand tool, spending tremendous time and effort drilling several holes.

Now all this is done in a matter of seconds, and without any effort or strain.

Necessary materials

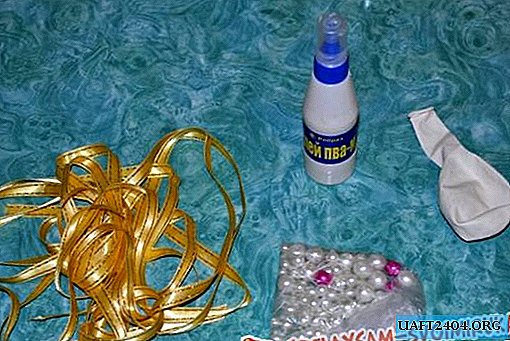

Everything can be made from junk, and you don’t have to buy anything, in fact. What you need to make:

- The electric motor is 6-18 V. I took it from an old tape recorder.

- DC power supply to the motor at 5-20 V, in accordance with the voltage of the motor. If there are differences in one direction or another, the volt is 5, then that's okay.

- Drill 0.5-0.9 mm. If not, you can buy at a local store.

- Ballpoint pen paste.

Tool:

- Cutter or wire cutter.

- Wires.

- Solder paste or solder flux.

- Soldering iron.

- 10 minutes of your precious time ;-)

Beginning of work

The first thing to do is cut a piece from the paste, about 2 centimeters. The inner diameter of the paste fits very well with the diameter of the motor shaft. Therefore, the paste is very tightly put on the shaft and holds well. If the paste dresses easily - look for a friend, they are different. Usually everything fits as it should.

Next, remove the tip from the paste with the ball, which I write. In order not to get dirty with ink, wash this tip with alcohol or cologne.

Then, with a knife or nippers, bite off a feather ball.

It turns out a kind of tube. We insert a drill, it should pass freely.

Now, to fix the drill, you need to solder it.

Drill the cutting part should not protrude too much. Wet with flux and solder with solder. Everything is soldered very well, regardless of the metal of the drill and pen.

We bite off the excess tip of the protruding drill with wire cutters.

We put a feather on the paste and a home-made drill chuck at the ready.

We connect to the existing power supply and drill. When connecting, look at the direction of rotation of the drill so that it rotates in the desired direction, and not in the opposite.

For power, you can use not only an adapter, but also batteries.

Watch the video of the drill

Share

Pin

Tweet

Send

Share

Send