Angle grinder is versatile in use - the tool is intended not only for cutting metal, wood, concrete and ceramics, but also for some other types of work: grinding, sharpening and polishing. For each specific operation you need a special disk.

So that the disks for angle grinders are always in a prominent place in the workshop, they are best stored on a special stand that can be easily made with your own hands. To do this, you will need a piece of square profile pipe and a piece of steel plate that will act as the base - the “sole” of the structure.

How to make a stand for storing disks

From a square profile of 30x30 mm, cut a piece with a length of 15-20 cm (depends on the number of discs that you want to place on the stand). Grind the surface of the workpiece to remove rust. If the profile pipe is clean, you can skip this step. Then we make markings on both sides at different heights to get "steps".

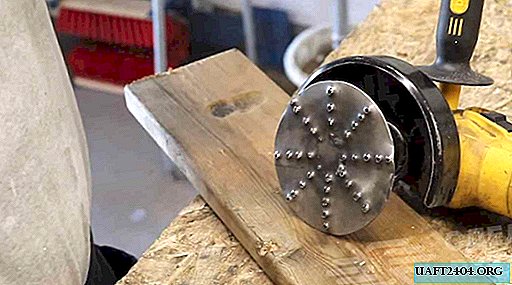

Using a grinder, we make cuts at a small angle - the thickness depends on the type of disc (for example, grinding flap, as well as grinding wheels for angle grinders are thicker than detachable). We weld a profile pipe with slots to the plate, the surface of which is also desirable to clean from rust.

We install a makeshift stand on a table or other place in the workshop and insert disks for the grinder into the slots. Now they will always be in sight and you do not have to waste time searching for them in tool boxes. Take note of this idea.