Standard plastic grease fittings with a nose, which are sold practically on every corner, although they cost a penny, are very inconvenient to use. Firstly, the nose is often clogged and you have to constantly pick it up with a wire or a needle. Secondly, these grease fittings do not have an adjustable dispenser, which causes certain inconveniences when high precision lubrication of mechanism parts is required.

But with the help of a home-made oiler with a dispenser, you can adjust the degree of oil supply at your own discretion and precisely apply any amount of grease. For this homemade product you will need a steel hex stand with a diameter of 5 mm and a length of about 6 cm, at the ends of which there is an M3 thread, a carbon dioxide adjustment faucet, as well as some other accessories.

The process of manufacturing a smart oiler with a dispenser

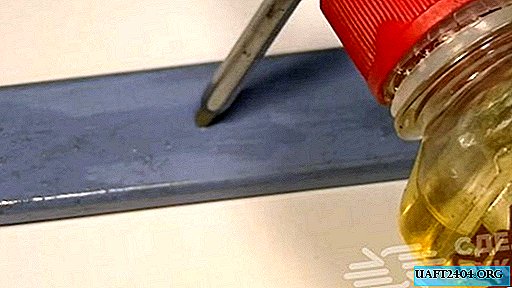

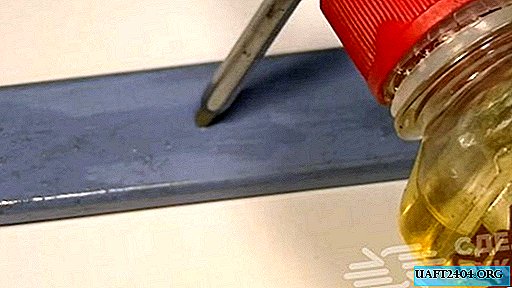

First of all, it is necessary to drill through the stand using a 1.8 mm drill (instead of the stand, you can use a thick-walled tube, bolt or screw of a suitable diameter). One of the most important components of this homemade product is the faucet for fine CO2 control, which is used in the aquarium.

The faucet itself must be made of stainless steel and have two inputs and one output. The inner diameter of the nozzles is 3.3 mm, the outer is 4.4 mm. In the outlet pipe we cut the M4 thread. At the next stage of work, it will be necessary to manufacture the missing components for the grease fitting from the trimmed brass bolt and screw.

The assembled design of the dispenser is screwed into the cap from the plastic bottle, and on the back there is a rubber gasket, a steel washer and all this is clamped with a nut. The cap with the dispenser is screwed onto the bottle and the oiler is ready.