From pieces of profile pipes, corners and other scraps of metal that are found in almost every workshop or garage, you can make convenient and practical to use a mini-vise for a drilling machine with an eccentric clamp.

Using this home-made device, you can quickly fix various workpieces made of metal, plastic and wood to drill through and blind holes in them.

Also, this clamp can be used for other operations on manual machining of parts and workpieces. To make a mini-vise with an eccentric clamp with your own hands, you need welding (preferably semi-automatic) and a grinder.

The main stages of work

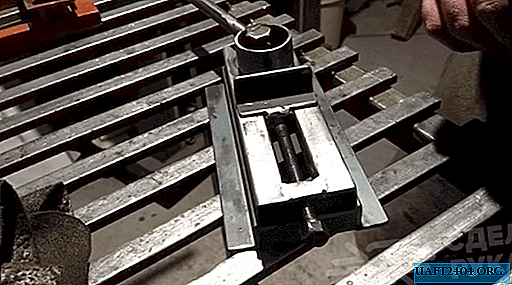

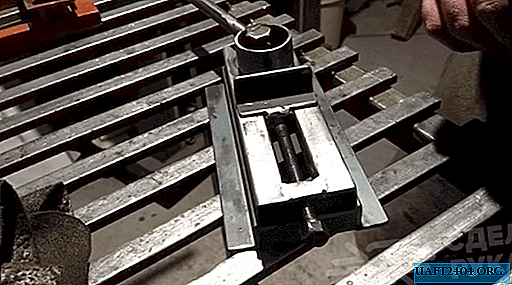

The first step is to make the eccentric element of the mini-vise itself. This will require a piece of steel pipe and a bolt with a nut. We screw a bolt into the nut, after which we weld it to the inner side of the pipe segment.

Then, from the profile scraps, it will be necessary to weld the main part of the mini-vise. A nut is welded between the profile pipes, into which a bolt of the eccentric mechanism is screwed. Then, the handle must be welded to the outside of the "cage" of the cam.

At the next stage of work, a clamping sponge is made from the corner, which is welded to the screw and is movable.

Then from the scraps of the profile pipe and corner, a “sole” is made, which is welded to the main structure. For a detailed process of manufacturing a vise with an eccentric clamp, see the video on the site.