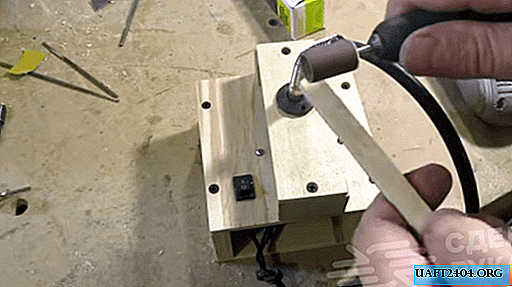

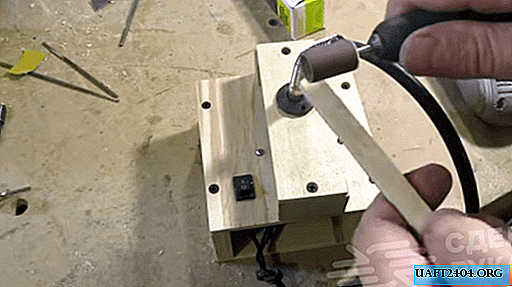

A drill is a very useful thing for a workshop. Using a drill, you can cut, drill and grind metal blanks. Moreover, this tool is easy to make with your own hands from improvised materials. For example, a drill can be made from an old engine from a bobbin (tape recorder).

Despite the small engine power (as a rule, engines with a power of about 6 W are used on bobbin holders), a homemade drill copes quite well with its task, taking into account that the scope of the tool is limited to the home workshop.

To make a simple drill, you will need a flexible shaft, an engine and an adapter with which the shaft will connect to the engine. The adapter can be made from ordinary aluminum blanks. But this will require a lathe.

The main stages of work

After the adapter has been machined on a lathe, we drill a hole of the required diameter in the center (and, if necessary, modify the file) so that the end of the flexible shaft can be installed. After that, we connect the flexible shaft from the drill with the motor shaft.

Next, we cut the blanks of the required size from a plywood sheet - we will make a housing for the engine and a "stand" for the flexible shaft so that it does not hang during operation. You will also need to set the power button.

Details on how to make a drill from an old engine from a bobbin reel can be seen in the video on our website. How do you like this homemade product? Write about this in the comments.