Share

Pin

Tweet

Send

Share

Send

Instruments:

- bit;

- mallet;

- drill and drill for the width of the groove;

- pencil and ruler.

Spike insert

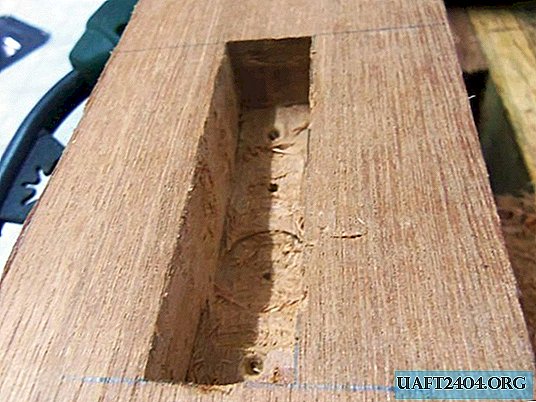

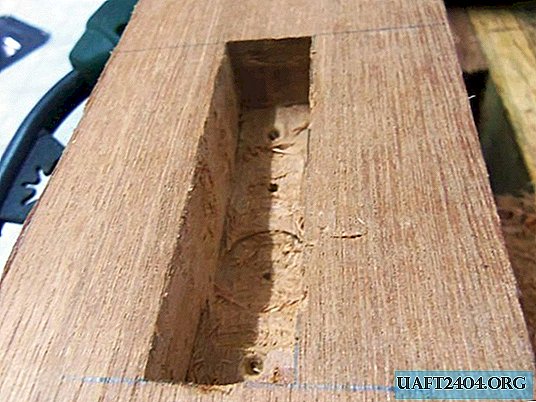

On the workpiece, the marking of the future groove is done. If it should be cross-cutting, then you need to draw on both sides, because otherwise you will not be able to get a neat insert. It is important that the width of the marking corresponds to the width of the available bit.

The bit is attached to the end of the marking and plunges into the tree with a light blow of a mallet. After that, his blade is attached after a few millimeters and is driven at an angle to the first notch. So you need to go to the very edge of the markup.

After this, the edges are cut down and a die cut is made along the middle. This allows you to separate the cleaved tree and clean it from the groove.

Next, several more passes are made to deepen the groove.

Once it becomes clear enough, you need to drill several holes along the groove with a drill of the same diameter. It is important that their depth be the same and correspond to the required length of the spike that will be inserted into the sample. In the manufacture of a through groove, you should first work with a chisel and, on the other hand, so that when drilling, the two recesses converge in the middle of the workpiece. If you break through only on one side, then on the other you get chips.

After drilling, thin wood partitions remain. This is done quickly if you additionally drill the walls at an angle.

What cannot be removed in this way is cut off with a chisel.

The result is a groove with smooth walls. It is important that its size matches the parameters of the spike. The bottom of the through hole may have irregularities; it is not necessary to grind it. This surface is still not visible, and after pouring wood glue, it will stick to the torn fibers even stronger.

Of course, connecting the workpieces using spikes and grooves is longer than using screws and other metal fasteners. But such a node looks much more attractive, and besides this, it is the most reliable. It will never allow play to appear between connected workpieces. Perhaps the first time the groove will not be so neat, but with practice its quality will improve.

Original article in English

Share

Pin

Tweet

Send

Share

Send