Share

Pin

Tweet

Send

Share

Send

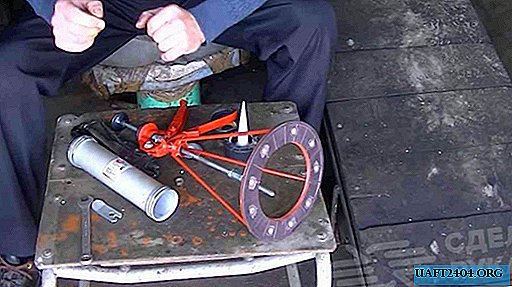

As the operating experience of the petrol scraper, in particular, made in China, shows that they often have malfunctions in the launch system, so they are often difficult to get started. Problems are usually associated with the magneto flywheel.

For those who are unfamiliar with this unit, we recall: this system, consisting of an ignition coil, a spark plug and a flywheel with magnets.

We have to deal with the magneto gap, more precisely, with the gap of the ignition coil and its guaranteed exposure. It is because of it that problems arise in Chinese units, which for several years were operated in domestic conditions or in the housing department.

But it happens that even in new products start-up is difficult, especially on a cold one. And in this case, usually the launch problems are due to the magneto gap. Most people who use gas mowing machines set a 0.4 mm magneto gap, as many manufacturers recommend.

What happens if this gap is adjusted and set to 0.25 mm? It turns out that when it decreases, the electric spark becomes thinner, finer and fulfills every beat even with slow turns of the magneto flywheel.

That is, by consciously reducing the gap, we thereby increase the likelihood of a normal start of the brushcutter without any unnecessary physical exertion and shortness of breath even when starting a cold engine.

The gap and the order of its exposure in different cases

As a template for setting the magneto gap, you can successfully use a strip of the required width and length, cut from a regular plastic bottle, for example, from under Pepsi-Cola.

It is only necessary to install it last, so as not to damage it during the repair work, using the same hair dryer for any purpose. After all, if it is warped by the effects of hot air, then there is no need to talk about the accuracy of setting the magneto gap.

It is with the help of a spacer cut from a plastic bottle that you can set the magneto gap of 0.25 mm with high accuracy, since its thickness is exactly the same. To verify this, it is enough to fold the strip four times and measure with a vernier caliper its total thickness, which will be exactly 1.0 mm.

We apply a spacer cut from a plastic bottle to the magnets of the magneto flywheel, put the ignition coil in place and fix it with strong 8 by 8 bolts, pre-filling the threaded holes on the body with a threaded lock.

We apply it to the bolts, twisting which, you must not forget to fix the mass terminal. It is better to use a screwdriver. We squeeze the bolts to the limit by hand with an ordinary manual screwdriver with a hexagonal bit, since the use of an L-shaped hexagon can lead to disruption of the faces of the bolt heads.

It remains, turning the flywheel with magnets, remove the plastic spacer and, while continuing to rotate it, check the quality (uniformity) of the gap when it is rotated from 0 to 360 degrees, which turns out to be ideal with this approach.

Some people use a doubled xerox sheet when setting the magneto gap, which is also acceptable, but using a spacer from a plastic bottle gives a better result. Moreover, it can be reused dozens of times.

It remains only to install body parts and you can start the engine to test how it starts and works.

Sometimes during operation, the attachment points of the ignition coil to the magneto body are deformed, which does not allow it to be installed reliably, since the holes in the coil and on the engine case do not coincide.

You can, of course, try to correct the defect, but it will be more reliable to put a new coil, especially since it does not cost too much.

All further actions are similar to the case described above, except that the heads of the bolts of the ignition coil can be mounted not under a hexagon, but under a wrench and a Phillips screwdriver. But this does not change the essence of the matter: the tightening of these bolts must be guaranteed to be reliable, as in the first case.

To assess the quality of the work done, you need to make sure that there is a spark between the spark plug electrodes visually after the final assembly of the engine. To do this, we connect it to the mass and begin to crank the engine using a manual or electric starting device.

Spark test has one caveat. If you jerk sharply at the kicks starter, a spark will appear even with slightly defective magneto magnets and even completely idle ignition coils. In this case, the presence of a spark is not yet an indicator of the health of the ignition system.

The quality of sparking can be judged only when it appears, when the magneto flywheel does not rotate too fast, for which the kick starter should not be pulled, but pulled uniformly and quickly.

Only in this case, the engine of the benzotrimmer or chainsaw will start without problems, both for the first time in the morning and throughout the entire working day (respectively, the so-called hot or cold start).

If, however, during the slow movement of the starter, a spark is not observed, then most likely you will have to change the ignition coil, set the magneto gap or change the spark plug.

The above-described practice of setting a clearance on chainsaws and chainsaws for five years has fully paid off. There were no complaints from users after such a repair. This really helps when launching not only Chinese brushcutters, but also European, and even branded ones.

On all units, regardless of manufacturer, setting a magneto clearance of 0.25 mm instead of 0.40 mm, recommended by manufacturers, gives excellent results. Some people offer clearances of 0.10-0.15 mm, but this is too small. After all, there is a certain thermal expansion of the parts of the ignition system, the body itself, the crankcase or the chainsaw, and such a small gap can disappear altogether, which can lead to breakdown (burnout), especially of the ignition coils. Therefore, a 0.25 mm gap is optimal from all points of view.

Share

Pin

Tweet

Send

Share

Send