Share

Pin

Tweet

Send

Share

Send

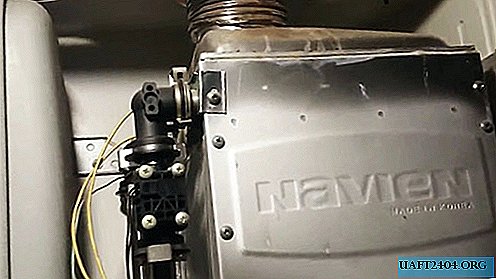

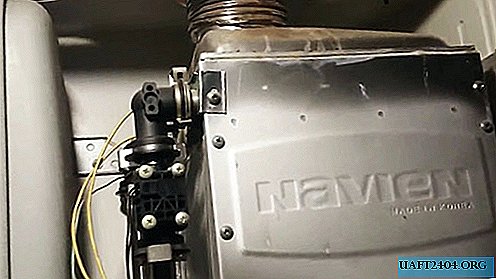

Even modern turbocharged boilers are far from ideal.

They have a very mediocre level of efficiency, so a huge amount of heat goes through their chimney. The author of the design came up with how to use the exhaust of a home boiler to heat his garage. His technical solution provides for the consumption of only 60 watts of electricity per hour, which are necessary to power the circulation pump and fan.

What will be required to assemble the heating system

Although the proposed method and cheap to maintain, but still have to spend money on materials. The good news is that part of the system’s components can be removed from damaged equipment or purchased at scrap metal. For installation you will need:

- electronic relay for monitoring power supply;

- 2 heat exchangers from gas boilers;

- sheet metal for the manufacture of ducts with diffusers;

- pipe made of cross-linked polyethylene or metal plastic;

- a broken air conditioning unit;

- fan (ideally native to the air conditioning unit);

- temperature regulator;

- electrical wire;

- non-freezing.

How does heating work?

The author of the design made it as experimental, therefore, many technical solutions were provided as temporary. As a result, the system still requires some improvement. Despite this, this principle can be done by heating in your workshop or garage even more efficient and aesthetically attractive.

Let's start in order. Near the gas boiler there is an electric relay, connected in parallel with the circulation pump, driving the coolant through the home system. Due to this, the equipment for heating the garage will be turned on only at the moment when the boiler is working. This eliminates the useless consumption of electricity.

At the outlet of the chimney of a turbocharged gas boiler, a box with an inlet and outlet diffuser is installed, inside it there are two small radiators removed from old boilers.

From the author’s house, exhaust gases and air rise at a temperature of 110 degrees through a chimney.

Moving through the box, they heat the radiators. Those are connected to each other in series with the tube.

A pipe made of cross-linked polyethylene with a diameter of 16 mm coming out of the box is laid in the garage and connected to a large radiator unit from the old air conditioner, transferring heat to it.

The radiator is equipped with a native fan, which stood with him on the air conditioner. He is powered to the network through a thermostat. Thus, the author ruled out non-stop operation of the fan. As soon as the radiator is heated to a temperature of 15 degrees, the fan is activated and begins to blow warm air into the garage.

A return pipe with a circulation pump comes out of the air conditioning radiator unit. It feeds back to the duct installed in the chimney of the gas boiler. It turns out a closed system, in which the coolant circulates in a circle, capturing heat in the duct in the chimney and passing it to the radiator unit in the garage.

The circulation pump of the garage heating system is connected to the mains through a relay installed in the house near the boiler.

Thanks to this, the coolant is chased in a circle only at the moment when the boiler is working and hot exhaust comes out of the chimney. The temperature controller with a fan on the garage radiator is powered from a conventional network. Anyway, the airflow will be turned on only at the moment when the actual temperature of the heat exchanger cells rises above 15 degrees, which is possible only with a working circulation pump. If you connect the electronic thermostat also from the relay, then from constant on and long-term shutdown its settings can come true, which is completely undesirable.

As a coolant in a garage heating system, an ordinary automobile non-freezing machine is used. At the highest point of the system, located near the duct in the chimney, there is a vent valve. In the garage, an expansion tank is naturally provided, as in any other heating system. The author has not yet dug up a heating main, it lies on a surface wrapped in thermal insulation. Of course, this does not look very good and leads to serious heat loss, and also causes a strong formation of condensate and ice.

Having decided to repeat this design, you can use more heat exchangers in the duct in the chimney. The author of the idea of the exhaust gases from the boiler give 40-45% of their own heat, but if there were more radiators, then everything would work even more efficiently. Naturally, the more massive the heat exchanger in the garage, the better the room will warm up. The author of the idea, despite the fact that he did everything temporarily to check and whip up, all the same, they always have a positive temperature in a concrete uninsulated garage, even in severe frosts. After the improvement, it will be possible to achieve real heat in order to work comfortably on car repairs or homemade products.

If you are interested in this idea, then be sure to watch the video where you will familiarize yourself with this useful homemade product in more detail and more clearly.

Share

Pin

Tweet

Send

Share

Send