Share

Pin

Tweet

Send

Share

Send

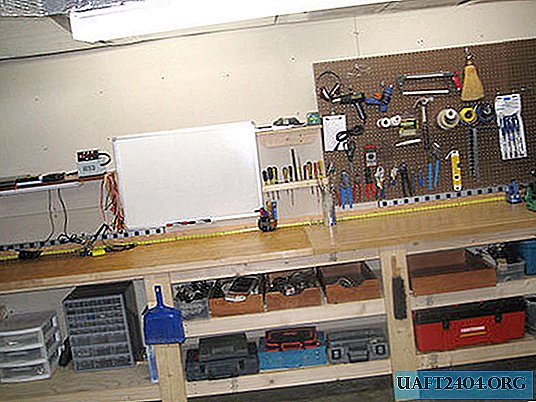

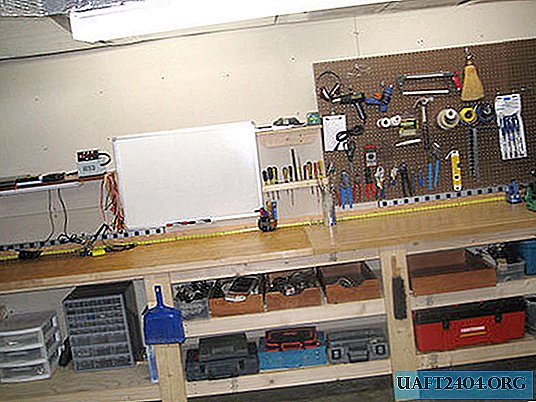

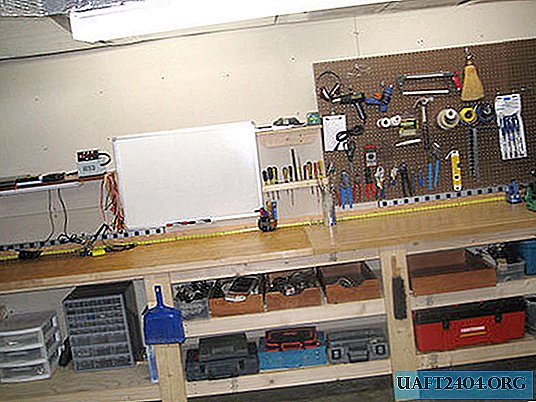

I think, sooner or later, every master begins to annoy the lack of a normal job. So it was with me: the room reserved for the workshop looked more like a warehouse or just a cluttered pantry, where the entire tool was pierced in the corners and at the same time dumped into one pile. In order to find something (and even less so), it was necessary to spend a certain amount of time and nerves. Is that familiar?

One fine day, I decided that I needed to deal with this mess: I decided to put things in order and organize a full-fledged work area with a functional and convenient workbench. I hope my example of organizing space in the workshop will be useful to others.

Necessary materials

For the manufacture of worktop countertops, I plan to use old wooden doors. There is also some lumber and old furniture in the “zagashnik”, which I will take apart if necessary. For workbench racks and shelf construction, I purchased 12 2-meter-long blocks of 50 × 120 mm and two sheets of plywood, which, for ease of transportation, were cut in half at the base. I also purchased perforated fiberboard for the stand, took two fluorescent lamps for lighting the working area, and bolts with nuts and washers, dowels and powerful self-tapping screws for a wrench to fix all the components.

First of all, you need to disassemble the rubble and free the wall for the construction of a workbench and shelving. During the cleaning process, at the same time, I sorted and sorted into boxes various parts, bits, bolts, anchors, nuts and other small things, which, as usual, are all mixed up. After cleaning the workshop has become much more comfortable.

Assembly workbench

After marking the wall (indicated the location of the horizontal supports and vertical posts), he began assembling the countertops. First, from a beam unfurled on the sawmill, I screwed horizontal supports to the wall for the working (upper) surface, as well as the middle and lower shelves. Behind the gypsum plasterboard casing, a cinder block wall, so that the supports were fastened with dowels and screws with a turnkey head.

Then he assembled the frame of the front frame on the floor, after which he began to assemble the structure. Since old doors will be used as a tabletop (one door is made of solid wood, the other is lined with laminate), therefore, I proceeded from the calculation of the width (depth) of the workbench of 80 cm. I began assembling the structure by attaching the upper struts so that the frame would stand on its own. Then he installed the lower and middle shelf from a cut-to-size plywood sheet. For fastening, I used ordinary wood screws.

The next step is the arrangement of countertops. He put both doors on the upper supports and screwed them to the side rails, the front frame and the rear supports using long bolts. Between themselves, two canvases connected by a wooden block, drawn by bolts through a through hole. He made the bolt heads recessed in the countertop, then sealed them and the seam between the two halves with putty on the wood and sanded them with fine sandpaper. To prevent the tool and small parts from falling over the countertop, I attached a wooden rail instead of the baseboard.

Now - the electrical wiring. To make access to the sockets convenient anywhere, I extended the cable from the central shield and connected one block of power sockets on the left and right side of the workbench (a frame made of shockproof plastic with a large number of connectors is, in fact, a very long block).

I hung a small shelf from the left edge above the countertop, and attached a small lamp to it from below, which will be an additional light source (a large lamp on two lamp tubes hung above the table about in the middle).

Other fixtures

I made a stand for hanging various tools from a thick perforated fiberboard. To ensure that there is a gap between the wall and the stand, I use 5 cm long plastic sleeves. I attached them to the back of the black electrical tape so that they do not come off the screw while attaching to the wall.

So that the coils with the wire did not roll on the floor, I built a simple rack: now the entire cable is in one place.

I also decided to attach an old plastic board: it is convenient to make any sketches or schemes on it.

There was free space between the board and the stand, I placed two shelves there: one for screwdrivers (a section of a board with drilled holes), the other for different little things.

At the end of the right edge of the workbench, I installed yews, which I fixed in the countertop with bolts through the through hole.

Now it remains to hang frequently used tools on the stand, and to sort the rest and other useful little things into boxes and arrange them on shelves under the workbench. For very small parts, screws and other trifles I adapted a plastic box - a very useful thing in the household!

As the finishing touches, I placed a fire extinguisher, a dustpan and a brush on the workbench racks to clean the working surface, and put a large waste basket in the corner.

Additions

Near the other wall I built a smaller workbench from one door leaf and hung another stand for the tool from the rest of the fiberboard. I think an additional work surface will not be superfluous.

I put a restored bookshelf in the corner of the workshop: I fastened it with metal corners so that it would not fall apart. On the shelves there is always something to arrange.

I also bought a couple of cool aprons at the “1000 little things” store: one on a mug for every little thing (I just liked it), the second is really useful, put on a bucket that is used as a carry. Really convenient: in the apron there are many pockets and a bandole for various tools.

This is how the workshop turned out: convenient and compact, where everything you need is at hand.

Share

Pin

Tweet

Send

Share

Send