Share

Pin

Tweet

Send

Share

Send

Will need

- Boards. Part of the pallet, part just lying in the country.

- Joiner's glue. Any glue on wood will do.

- Rivets.

- Sheet of iron.

This is the most basic, you will need something else in detail, but more on that later.

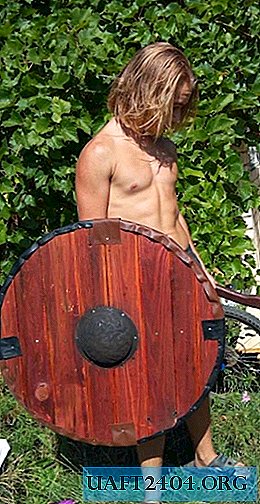

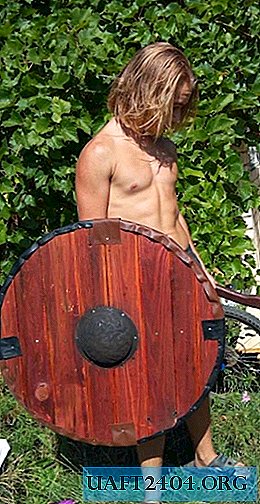

Shield Making

We are not looking for simple ways, so we will not make a shield from plywood or a furniture board (a shield from a shield, cool), but from boards. Here are these:

And you ask me how to make something cool out of a bunch of these old boards? But no way! First you need to plan out all the blanks.

In the process, I replaced some of the original boards. Light attrition with time gives wood a special charm, but frank rot is already superfluous. If you buy a edged board (you can take one long one, and then saw it into the necessary parts), then you won’t have to plan it strongly, but if you go along a difficult path and take old boards, you will have to adjust the ends. This is me to the fact that all the workpieces should fit well together. This is necessary for the next stage - gluing. Oh yes. All boards should be no more than 10 mm thick. The shield should be light, the historical Viking shield could be in the middle of 8 mm, and already 5 mm to the edges. More than 1 battle of the shield and should not have been missed, only the survivor umber, but more on that later.

I glued all the boards on a workbench, on three sides of which were attached stops in the form of bars. I glued the ends with wood glue Moment. Very good glue, by the way, I told them the electric guitar deck, and glued the furniture, and the shield. All ends were glued and joined in turn. Then the third emphasis was attached to the workbench, which clamped all the boards, and two more boards were laid on top, and gypsum blocks were placed on them. This is so that all gluing does not lead. I left the glue to dry for about a day.

After a circle was drawn 74 cm in diameter. Not the largest or smallest, in general, I chose this size specifically for myself.

Next, I started making umber. In general, it should be made of approximately 4 mm steel, but then I decided to follow the path of less resistance. I found an iron plate a little more than one mm thick, and began to arch it in the hemisphere.

To do this, I dug a pipe into the ground, put a plate on top, constantly heated it with a burner, and beat an old dumbbell.

After the holes were drilled around the edges of the umber, I also cleaned it from old paint and smoked it on a fire. Also, leather was glued to the inside of the umber.

Now we mark in the center of the shield a hole for the umbon and carry out drilling and chisel work. That is, we drill along the edges of the marking, and after we knock out the circle with a chisel, those places that are not drilled. And also we drill the umbon and the shield itself at the edges of the rivet hole.

Fasten the umbon to the shield with rivets. And paint the shield with stain. I used a mixture of mahogany and mocha. It turned out pretty interesting. With different lighting and different angles, the color is either dark saturated or dull light.

Next, I made a handle from a pine bar. Why from pine? Because lying around at hand, why else ?!

The handle is also attached to the shield with rivets and to each board to strengthen the shield.

Then I found black and brown skin, which was cut into strips and nailed to a shield on small cloves. On the flip side, I had to additionally attach all the skin with a large stapler, because the cloves were too short. Go to the store and buy the right length carnations? No, not our option.

This completes the manufacture of the shield. And yes, we tried to beat him with an ax and, lo and behold, he stood it! It’s better not to repeat this, even if you make a shield and you are not sure about it.

There is a rune ax, there is a shield, it remains to make a dragcar and go on a hike!

Share

Pin

Tweet

Send

Share

Send