Share

Pin

Tweet

Send

Share

Send

I will tell you three reliable ways to connect the wires in the junction box, which I use myself and recommend to others.

Wire welding

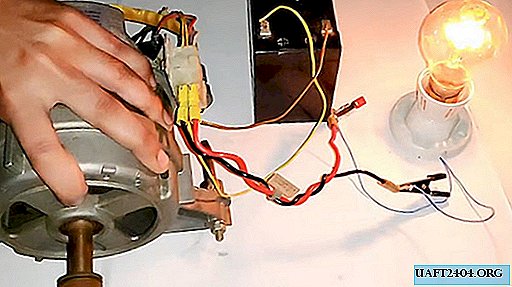

The first in terms of reliability is wire welding. It is produced by a special welding machine using a graphite or tungsten electrode. In view of the melting of the metal gives mixing structures and the wires become as one. If possible, use it.

Pros:

- The most reliable connection of all presented.

- Suitable for aluminum and copper wires.

Minuses:

- Requires special equipment.

- Time consuming and not always applicable.

Soldering wires

The second most reliable method for connecting two or more wires is soldering. It is produced by a conventional soldering iron using conventional solder and flux used in radio engineering. This is the most affordable way.

First make a twist of a few centimeters, and then seal it along the entire length.

Pros:

- Very reliable connection with the proper length of the soldered twist.

- Available to most home masters.

Minuses:

- Time consuming and not always applicable.

- Applicable only to copper wires.

Crimping wires

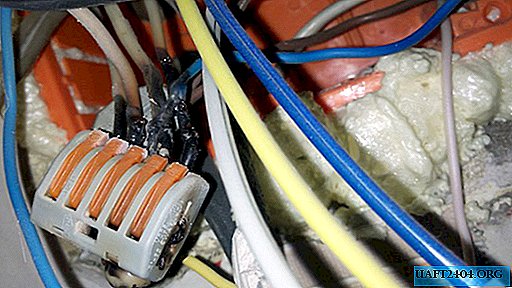

The third most reliable method is crimping wires with ferrules. In view of its speed and reliability, it is often used by electricians when laying wiring in new homes.

Pros:

- Very fast, requires a minimum of time to create a reliable connection.

- Suitable for aluminum and copper wires.

Minuses:

- You must have special crimping pliers and ferrules.

Conclusion

Regular twisting, screw terminals, terminal blocks, caps, clamps - in my opinion, an electrician with 20 years of experience is not a reliable connection of wires! By reliability, I understand that the connection is able to withstand the same current without excessive heating that the wire itself is designed for the entire period of operation.

Of course, I use both VAGO terminals and twists in my work, but I try to do this either in light wiring, where the maximum current does not exceed 5 Amps, or in other examples with low current. Connecting fixtures with such terminals is very convenient and fast, you can’t argue.

Now many people will begin to argue that VAGOs are very reliable, rated for high currents of 32 A, etc. But my many years of experience, unfortunately, argue the opposite.

Therefore, the three compounds given at the beginning can be used and in the future not to worry about the consequences.

Informative video on the topic

Share

Pin

Tweet

Send

Share

Send