Share

Pin

Tweet

Send

Share

Send

To date, the strip foundation has been widely used in low-rise construction. It is relatively simple to manufacture, reliable, and the cost of work is not expensive.

Before building the foundation, you should familiarize yourself with the manufacturing technology, this will help to calculate the costs. It is necessary to take into account the composition of the soil, freezing of the soil and the total weight of the building. From these indicators, the width and depth of the foundation will be determined. It is also necessary to take into account the fact that the depth of the foundation in any case should be lower than the depth of freezing of the soil.

The construction of the foundation begins with the preparation of the site: clearing, garbage collection, as well as leveling the surface. Next, the perimeter is marked by the number of load-bearing walls. Stakes, which will be beacons, are driven in at the corners of the intended perimeter. Be sure to check the angles so that they are 90 degrees, and also check all the diagonals. The deepening of the foundation depends on the particular climate, soil, as well as the material that will be used in the construction of the building. However, the minimum depth should be 400 millimeters. The lowest point located at one of the outer corners will be the reference point for depth. After determining the depth and width of the foundation, excavation is carried out.

Having chosen the desired depth around the perimeter, sand is poured at the bottom of the trench, then it is rammed, and the sand must be moistened with water. The thickness of the sand cushion should be 200-300 millimeters. It is very important to monitor the horizontal sand cushion, there should be no slopes.

Formwork is made of edged boards. A feature of such a system is the flat surface of the material used, which will greatly facilitate the decoration of the outer part of the foundation. The boards have a certain size, this makes it much easier to adjust the height of the structure. Blocks of the same size, made up of boards, are installed at the bottom of the trench, strictly vertical, are aligned in height and are well fixed.

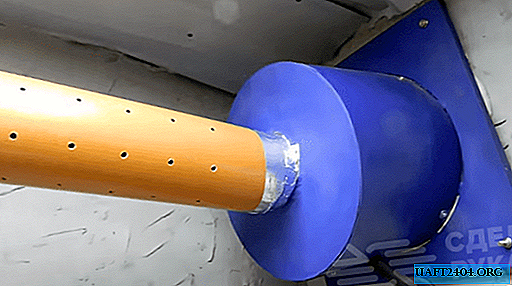

The reinforcement process is a very important point in the production of the foundation. The reinforcement cage gives strength and flexibility to the concrete base. When forming the frame from the reinforcement, you should avoid fixing the reinforcement by welding, a special knitting wire is well suited for this. The distance between the longitudinal rods of the reinforcement should not exceed 30 centimeters, and between the vertical jumpers from 30 to 80. The reinforced frame should be placed so that its base has an indent from the borders of the base from 3 to 5 centimeters. At this stage, it is necessary to lay all the transitions for communications, otherwise in the future it will be necessary to destroy the monolith.

Concrete is poured in one approach, only in this case can a monolithic foundation be achieved, but there is no need to rush. The solution is served in portions and distribute it around the perimeter. Ramming the solution is mandatory in order to avoid voids and displace excess air. This is done with a special concrete vibrator. Upon reaching the specified height, the surface is leveled. Further, the foundation of the foundation needs care within a month: if the weather is rainy, then it is covered with film, and in hot weather, it must be moistened with water (1-2 times a day) so that cracks do not appear in the concrete. After a month, construction work can be carried out on the foundation.

Share

Pin

Tweet

Send

Share

Send