Share

Pin

Tweet

Send

Share

Send

Gravity heating system with water circulation due to the temperature difference (and hence density) of the coolant in the direct and return pipes, can be mounted and used only for small one-story houses. Today, for this purpose (and for large cottages of 2-3 floors - necessary), circulation pumps are used that have low power (usually up to 100 watts).

How to install a circulation pump in a heating system

We will consider this procedure using the GRUNDFOS product as an example, but everything that will be discussed below can be applied to other brands of pumps with some minor refinements.

Pay attention to the main technical characteristics of the pump, which are indicated on the product itself. Of particular interest to us are power indicators. Our copy has 3 modes for this parameter: 25, 40 and 60 W, which will allow you to adjust the intensity of the coolant circulation depending on the desired temperature in the room and the actual one on the street.

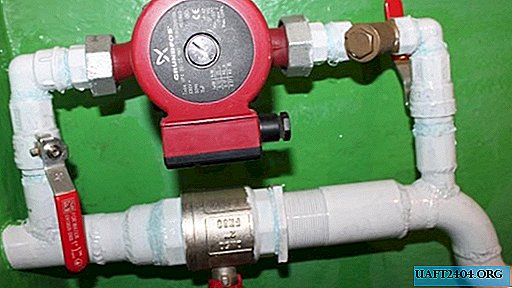

In the case under discussion, the circulation pump is installed at the outlet of the gas boiler using a bypass. Under the bypass, we insert a ball valve into the outlet pipe itself with the help of two bends welded to the outlet pipe. The working position of this pipe fitting is closed. It opens (but the valves at the ends of the bypass are closed) only when the circulation pump does not work for any reason (no electricity, breakdown, replacement, etc.).

Since the installation of the pump is carried out in an existing heating system, you can not do without welding.

Moreover, the welder must be highly qualified, since the overhangs will have to be welded into a pipe that is close enough to the wall.

Before the welder arrives, it is necessary to drain the water from the system and prepare two runs for the ball valve, with which it will be permanently welded to the outlet pipe. In case of failure, the crane will have to be cut and replaced with a new one. But since the main position of this valve is closed, its service life is comparable with the service life of the entire heating system. Therefore, there is nothing to worry about.

The bypass with an inch thread is a symmetrical assembly with a pump in the center, to which brass corners are attached on both sides with the help of "American" nuts (at the entrance - with a coarse filter). Next come the cranes, to the ends of which are screwed, which are used for welding to the outlet pipe. Places of threaded joints must be sealed with gaskets or windings designed for high and constant operating temperature.

The circulation pump, as already noted above, has three power modes, set using a switch located on the housing of the hydraulic supercharger.

Next, a section is cut out on the outlet pipe, which will be replaced by a ball valve with bends.

First, the bypass drives are welded vertically upwards, then horizontally - by a ball valve.

The main thing in this case is not to instill the thread of the drives with molten metal.

At the end of the welding process, a ball valve is screwed into the slopes intended for it. In the same way, a bypass is collected in series with the circulation pump in the middle. Moreover, the axis of rotation of the pump rotor should be horizontal. This will ensure a long and trouble-free operation of the hydraulic unit.

All threaded connections are carefully sealed and tightened with tools of the appropriate size and shape.

For reliability of assembly and increase aesthetics, it can be covered with paint to match the color of the pipes of the heating system.

Before connecting the circulation pump to the power supply network, it is necessary to set the taps in working position: on the outlet pipe - closed, on the bypass - open. It is impossible to allow, even for a short time with the boiler running, a situation where all the taps would be closed. This can lead to failure of the heat generator.

Tips and comments

Sometimes even experts believe that the circulation pump must not be installed on the straight pipe, but on the return pipe of the heating circuit, explaining that the water temperature is lower in it and therefore the pump will last longer.

However, this argument is not convincing, since the difference in water temperature at the inlet and outlet of the boiler rarely exceeds (and this is unacceptable!) 20 degrees Celsius. And this circulating pump, and all similar ones, are designed for the temperature of the pumped liquid heated to 100-110 degrees Celsius.

The only factor determining the installation location of this unit for organizing the circulation of the coolant is the ease of installation and maintenance during operation. But there is one exception. It concerns solid fuel boilers, which are not so easily and quickly extinguished when they enter the operating mode.

Therefore, if such a boiler is very hot, and the pump stands on the outlet pipe, then steam will go into it, which the hydraulic pump of this type is not able to pump. This will further exacerbate the heating of the boiler and accelerate its breakdown.

Therefore, on solid fuel boilers, it is more expedient to mount the means for ensuring the circulation of the coolant on the inlet pipe. At least you will have not 5, but 30 whole minutes to take action and put out the boiler.

It is necessary to carefully study the installation instructions for this circulation pump: the electrical box can not be installed at the bottom. If water flows, it will flood, a short circuit will occur and the pump will fail. This box is easy to rearrange and should stand on top or side. Also, the coarse filter should be directed strictly down.

Share

Pin

Tweet

Send

Share

Send